The best bits to drill holes in your FR-4 board are tungsten carbide bits. They are, however, more expensive. You can also use HSS (high-speed steel) bits, but they will quickly dull. To drill larger holes start with a small bit and then progressively go larger.

Have a good working light shining at the board. This is crucial to get the holes well centered, especially for smaller bits.

When drilling holes in a board that has several hole sizes (and most do), drill smaller holes first. That way, if you accidentally drill a hole that does not belong to that class (size), you would drill it again with a proper and larger bit. If you do the other way around, you may end up with a larger hole where a smaller one was needed.

You will probably end up using 2 different drills: one for board mounting holes and another one, perhaps a Dremel tool will CNC micro-bits, for board through-hole parts and vias.

When using a Dremel tool in general, the smaller the bit, the higher the rotational speed should be. Very small CNC bits easily snap and they will snap with the smallest lateral move. It’s really difficult to do it by hand so getting a good Dremel press will pay off in the long term.

Wear protective glasses while drilling!

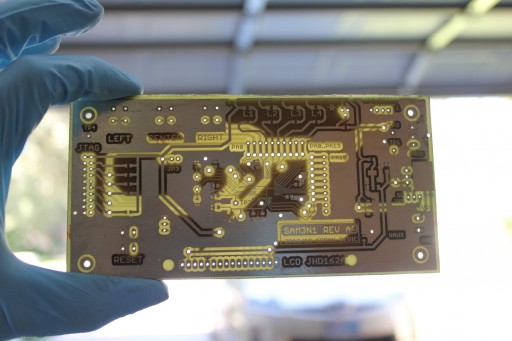

Using digital calipers, I measured each component pin, rotating it to get an approximation of the largest diameter. Those are the minimum dimensions to fit each part. As it turns out, some just did not fit and I had to drill again using one step larger hole. I like a very tight fit – don’t like parts to wobble when I insert them before soldering.

This table shows some of the parts used on this board and the corresponding bit sizes:

Drill using CNC RED bit: #65 0.88 34 mil Potentiometer 0.50 20 Power socket pins 1,2 0.60 23 LCD connector (F) 0.72 28 Power socket pin 3 0.83 33 Drill using CNC BLUE bit #61 1.00 39 mil Push button (small) 0.68 26 (*) Push button (large) 0.79 31 (*) Std headers, JTAG 0.79 31 (*) Molex (RS232) 0.85 33 (*) 7805 0.89 35 Drill using CNC PURPLE bit #57 1.13 44 mil Terminal block 1.03 40 Drill using CNC WHITE bit #55 1.32 52 mil Vias (#16 Ga) 1.32 52 Drill using HSS bits Standoffs 2.33 92

(*) I empirically found that in spite of their pin size, these parts fit better when holes are one size larger.

Tools: Drill press, bits (tungsten carbide or HSS), protective glasses, Dremel tool, a vertical stand for Dremel tool, CNC bits