Even tinned, the PCB traces will still corrode. Soldered joints will also oxidize since the solder is exposed to air.

After soldering, the board could be further protected by applying a coat of clear lacquer. The lacquer dries fast and can be soldered through afterward if needed.

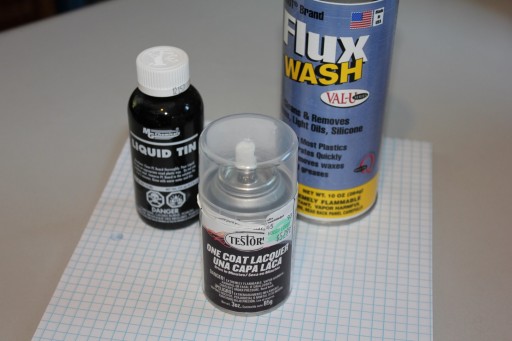

I use this lacquer for final board protection:

http://www.testors.com/products/137179

I found it at a local Hobby Lobby store. It dries in 20 minutes and gives that “wet” and polished look. I applied it after soldering most of the components, but before soldering connectors, push-buttons, and some other components. I coated the top side after putting SMD components, then soldered a few through-hole parts (terminals, etc.) and then coated the backside. I protected SAM3 and SMD LEDs by sticking on small cuttings of painter’s blue tape over the components before spraying it over.

All the soldering done after this lacquer was applied did not affect the quality of the joints in any way. Later soldering of workarounds and corrective jumpers over it definitely evaporated some of the protective coatings at specific spots, but those places are not obviously visible and it still looked and worked well.

Spray outside and follow the instructions: don’t spray directly at a board but use a sweeping motion. This unfortunately appears to waste a lot of sprays as you are passing in and out across the board.

Tools: Testors wet look clear coat lacquer, nitrile gloves